SAPCO has fully integrated its production channel (from the production of ceramics to the finished product), and therefore offers a great diversity of jobs with a large breadth of activities. At SAPCO, one can occupy multiple positions in the production area but also in the research department, as well as in quality and method. Jobs on the supporting and commercial department are also available.

The large range of jobs in the production area make available to employees the possibility to expand their technical skills and knowledge by working in 3 different factory floors: ceramic, electrodes, and the automatised mechanical assembly line. Therefore, at SAPCO, there is a richness in products and processes which allows employees to renew their skills continuously.

The modernisation and automatization of our equipment offers great opportunities for employees to develop their skills in the use of specialised machines. In this regard, SAPCO has put in place a large training program to adapt employees’ knowledge, increase their qualification, and therefore their employability. In addition, SAPCO is present in more than 25 different countries and continuously increases her growth internationally. Employees are therefore able to discover enriching and diverse work methods.

You will find below some examples of jobs here at SAPCO.

Engineering

The first step of the product’s manufacturing is its conception, a job taken by our expert technicians. This step is crucial to produce a quality product which meets customers’ demands.

Research technician (see job description)

“My job consists of turning a customer’s plan of a product into a finished product. I work in the conception of products and of new machine settings, as well as administrating the production. I am able to interact with a lot of different people, including the different factory floors but also the commercial and methods/maintenance departments.” – Research technician.

Methods maintenance supervisor (see jobs description)

“My work consists of supervising a team of technicians in charge of the conception of prototypes, of conducting feasibility studies of those prototypes, and of verifying the capability of our machine to manufacture those products, as well as resolving technical problems and issuing trials. I also manage another team in charge of the administration of machines and of the development of new machines. On top of this there also is the improvement of production processes. What I like about my job is the creativity and the liberty to take initiatives, which makes me get out of my comfort zone. I really feel like I am progressing in my skills and career, and that I’m helping the company grow.” – Methods maintenance manager.

Production

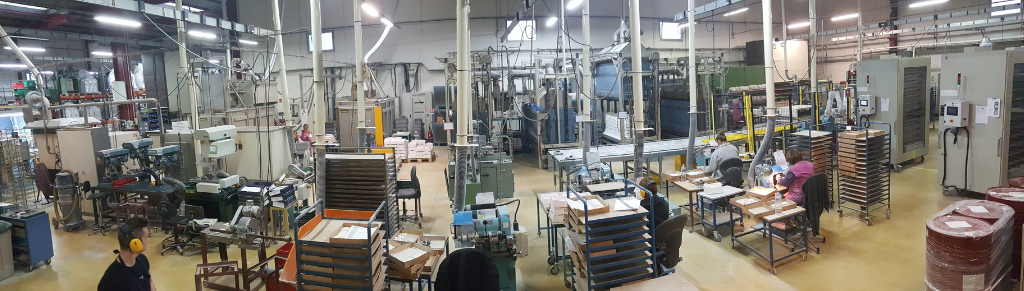

Once the product is designed, it takes form in our factory directed by our 60 employees who work meticulously to give customers the best quality possible. The 3 main factory floors are the ceramics, the electrodes, and the automatised assembly line, and each floor encompass various production jobs.

Machine regulator (see job description)

“A typical day for me starts with the organisation of my day and of my week with my team leader. I allocate work to my machine operators and control the first few pieces produced to make sure the machine parameters are good. I also do regular unexpected controls of machines to make sure the products are still in compliance. I like working as part of a team because I feel useful sharing my knowledge with my machine operators; it’s rewarding to see them gain in autonomy. I also like regulating machines, it becomes playful, almost like a game.” – Machine regulator

Team leader (see job description)

“My daily activity consists of leading a team of around 15 people, but also of organising and anticipating the machine parameters, verify the equipment, and do regular controls. What I particularly like about my job is the manual activity, manipulating tools and machines, but also the autonomy I have in the organisation and administration of my team.” – Machine regulator and team leader

Line operator (see job description)

“I supervise the assembly of components on a specialised machine to produce ignitors for different customers. Daily, I work as part of a team, either in the morning or in the evening, and I need to fill the machine up with components, start it up, produce, and control my production. It’s a position which requires extensive knowledge about the machine functioning, which is why I was specifically trained to its use. What I like about this job is the good atmosphere on our factory floor, and the autonomy I have to intervene on my own to adjust certain malfunctions of the machine, I feel responsible for it.” – Line operator.